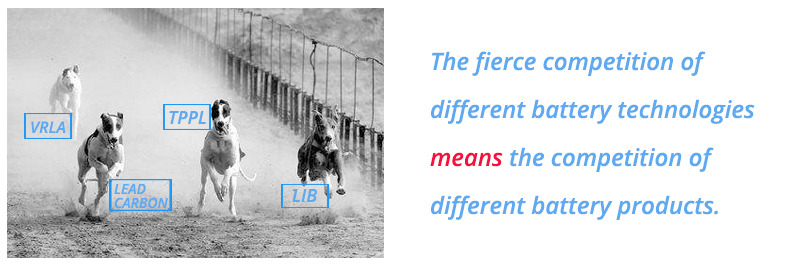

With the acceleration of global industrialization, users and the environment have placed more expectations on the performance of lead-acid batteries (such as high energy density, high reliability, fast charge acceptance, high rate discharge performance, energy saving, low carbon, lower total cost of ownership, etc.). The traditional technology of lead-acid batteries has the following problems: accelerated corrosion of battery plates, increased self-discharge rate of batteries, rapid water loss and large internal resistance variation. Based on the above requirements and problems, Thin Plate Pure Lead (TPPL) technology emerged. At present and in the future, with the rapid development and large- scale application of lithium-ion battery, the development of thin-plate lead battery is facing a direct competition and challenge.

What is the thin plate pure lead battery technology?

1. Technical summary of thin plate pure lead products:

(1) Monomer: thin plate, more plates;

(2) Grid: vertical structure made of lead belt punching technology; grid alloy Pb or Pb Sn (corrosion resistance);

(3) Electrode plate coating technology, uniform weight and uniform thickness of single plate;

(4) Bus-casting and welding, inter-cell connection through-wall welding, and cover groove sealing heat sealing process;

(5) TPPL (Thin Plate Pure Lead) thin plate pure lead technology;

(6) CCPP (Continue Casting Punch Plates) manufacturing process.

2. Product characteristics and service conditions of pure lead batteries:

Fast charge: 0.5C or greater charging current;

Cycle Performance: PSOC (fully applicable to 20-90% partial state of charge applications);

High temperature: suitable for long-term high temperature floating charge or cyclic application (35-50 C);

High power: 5/10/15 minutes high discharge rate, good safety and consistency.